IAT387 Directed Studies is a special course in which a group of students work independently with a SIAT faculty member to agree on a research topic and conduct independent reading and research. Our project revolved around the design of a specialized snorkel accessory tailored for individuals facing medical challenges that affect the oral region of their face. We started with the intention of delving into the field of 3D design, specifically within the realm of user experience & industrial design, all while addressing the unique needs of our potential customers.

Instructor: Kenneth Zupan

Team Members:

Walter Xu ( Ideator, 3D Modelling Lead, Prototype Cutting & Trimming Lead )

Rishabh Johri ( Researcher, Business Guru, Ideator, Prototype Finishing Lead )

Sarah Daniels ( Researcher, Visual Designer, Ideator, Prototype Assembly Lead)

Duration: 3 Months

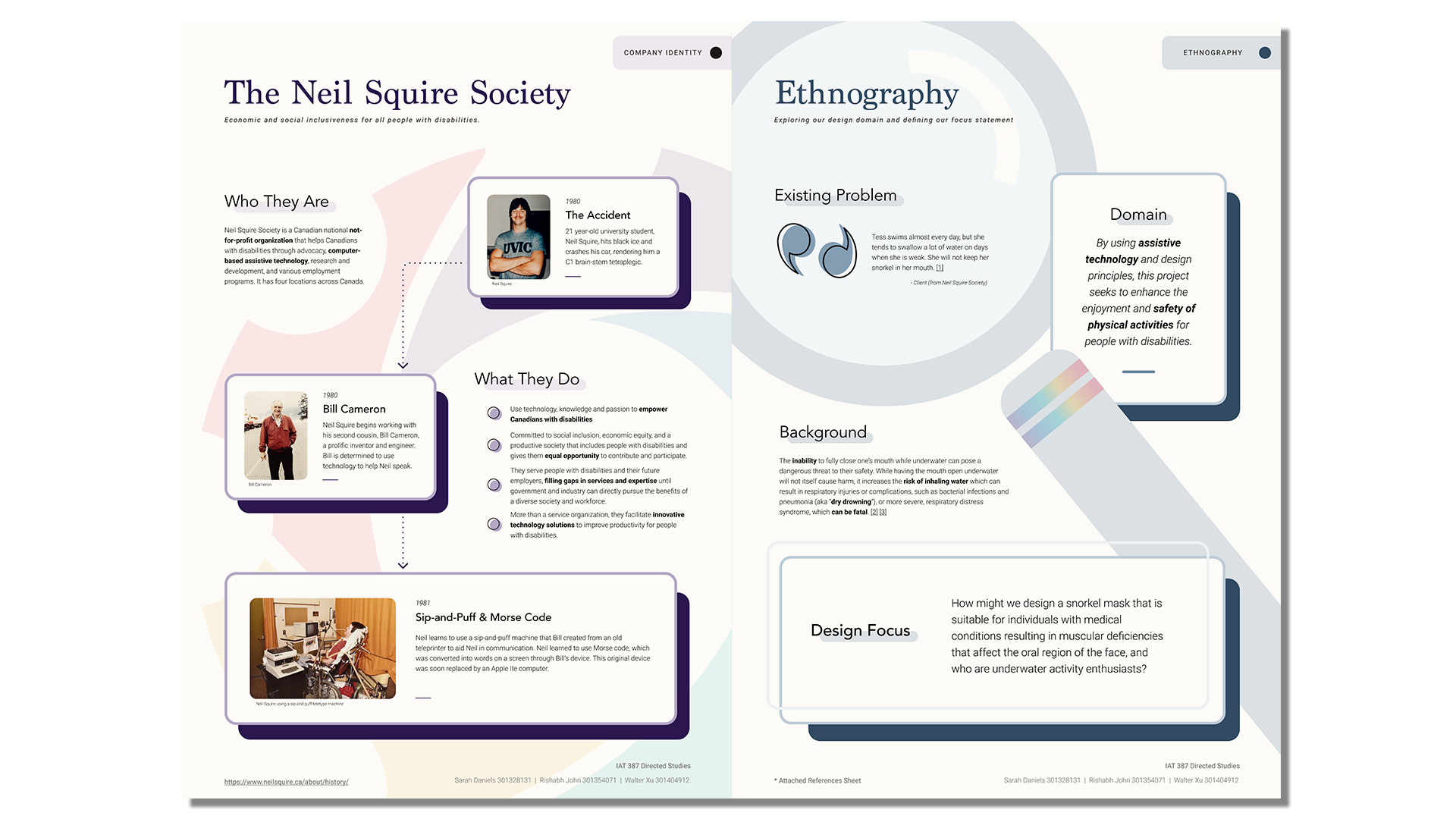

The motivation for this product came from an inquiry on the Neil Squire Society Community Board - a Canadian national non-profit organization that helps those with disabilities through advocacy. We came across an individual who wanted to find some way to "keep her snorkel in her mouth" as she 'tends to swallow a lot of water on days when she is weak" (anonymous client).

Following the preliminary research stage, we determined our initial driving question/design focus to be:

How might we design a snorkel mask that is suitable for individuals with medical conditions resulting in deficiencies that affect the oral region of the face, and who are underwater activity enthusiasts?

Research Poster of Neil Squire Society

We first looked at the snorkels available on the market and their limitations. We selected and studied both Cressi and Odoland brands of snorkels. we found that currently the only solution to our audience's problem are full face mask snorkels. However, there are still many problems, such as water leakage due to the inability to fit all faces.

Taking into account the previously defined design focus, pain points and goals of our target audience, and review of existing solutions we have the opportunity to create an affordable adaptive device that is compatible with existing snorkeling gear. We aim to create an attachment to standard snorkel tubes that will secure the mouthpiece to the face regardless of mouth or muscle control. This attachment will also not interfere with existing goggles.

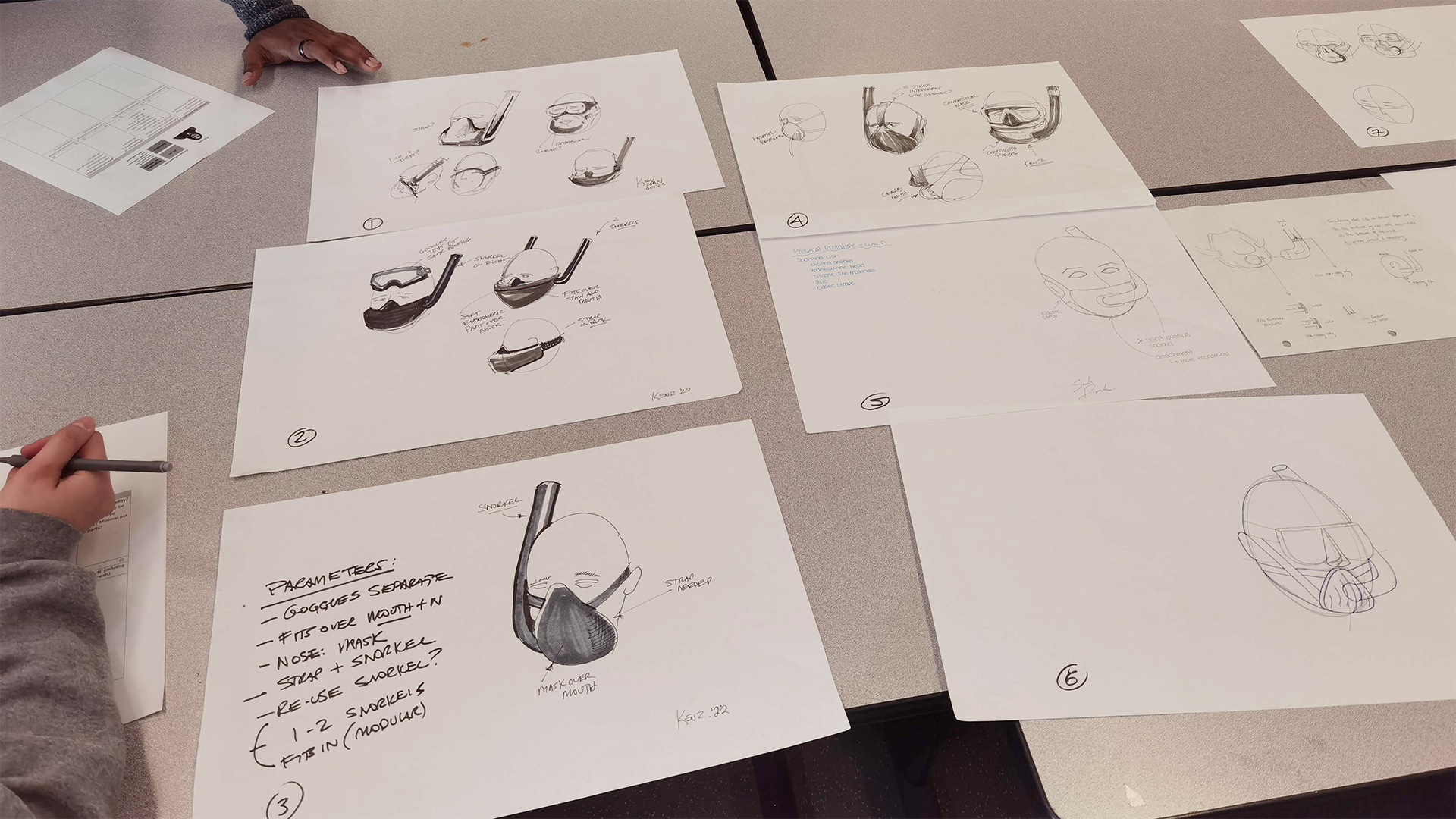

Ideation Sketch On Paper

According to the initial exploration, we chose two different mask designs to explore more. We found that the style of the tube in the middle would affect the comfort of the user, as the pipe blocked the view. Therefore in order to match the diving glasses, we chose the mouth-only and side-tube style for the next iteration.

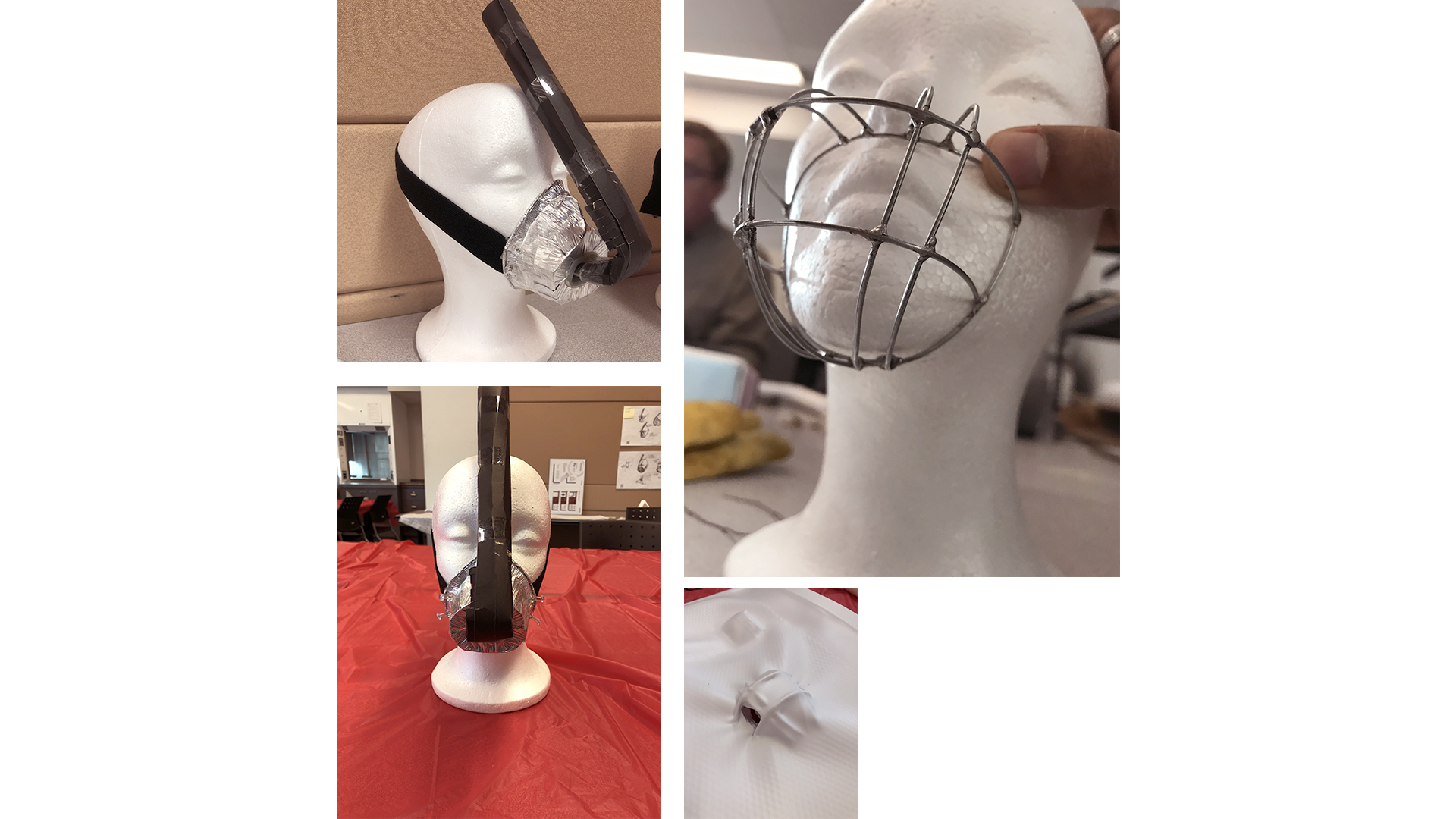

For medium fidelity, we further optimized the ergonomics of the mask, making it more in line with the curve of the face. Using tin-welded wire to make the frame, we determined the base shape and the size of the mask. We failed to vacuum press a cover on it because of the large gap between the frame.

Low Fidelity (Left) & Medium Fidelity (Right)

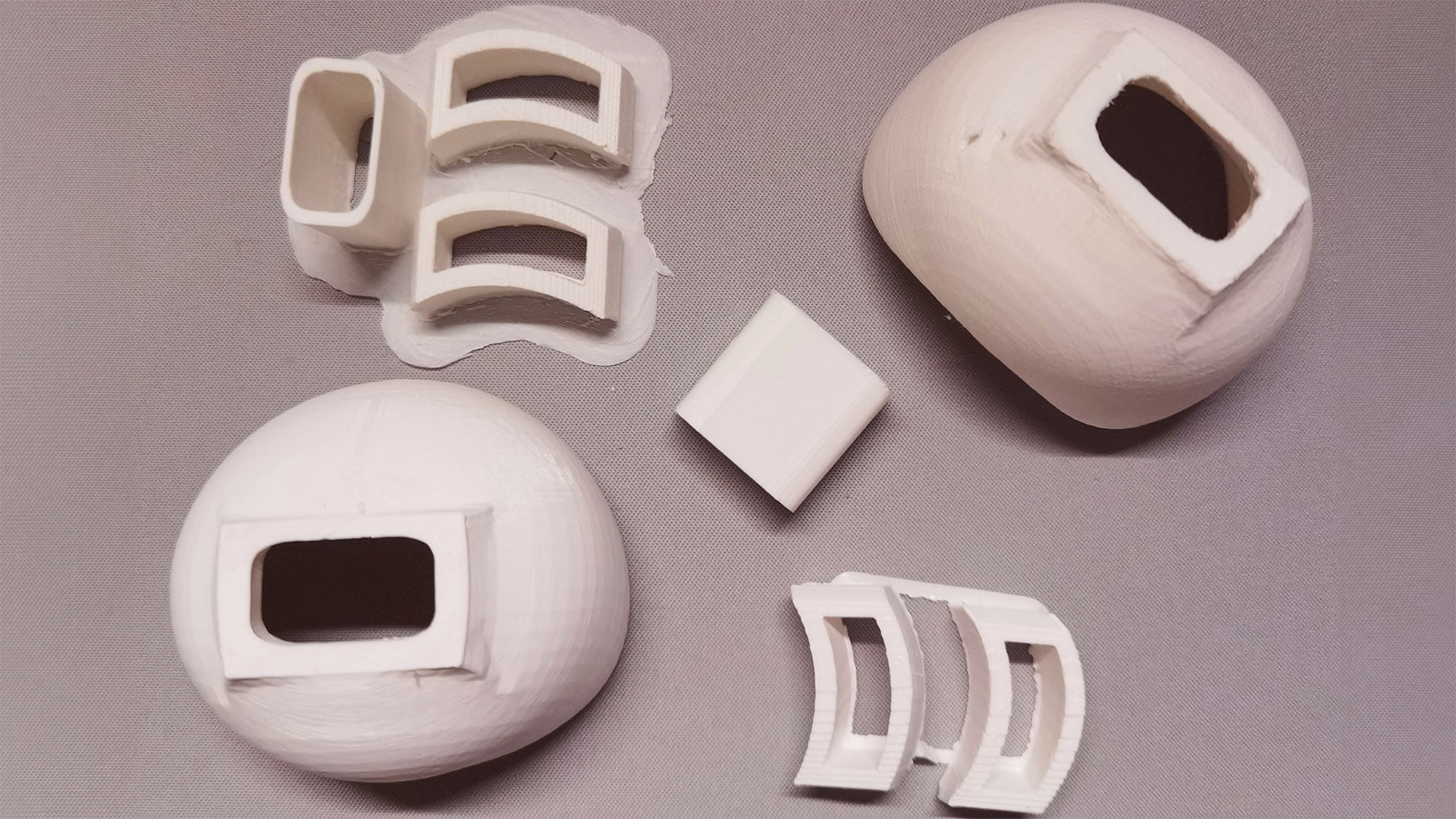

Once approved, I converted the medium fidelity model into a digital model for 3d printing (Hard ABS). Using super glue to glue all components and cellophane to increases the thickness of the mouthpiece attachment ; we began assembling. The use of cellophane made for a better seal between the tube and the mouthpiece. The black knit elastic headband was used to imitate the silicone headband.

The 3d digital rendering I did gave us the confidence in the product. It fits more closely to the shape of the user's head and provides more tension to ensure the fit of the device shell. User's comfort is also enhanced by the reserved ear cutout design.

3D Print Components Using Different Printing Methods

Once we finished the meticulous process of assembling the print, we took it upon ourselves to personally test its practicality by trying it on. We immersed ourselves in the unique experience of its use. Despite our best efforts, however we did not receive a response from the anonymous person who made the initial post.

Overall, our design is an economical, sleek addition to existing snorkeling gear. We encourages users to utilize their existing equipment, saving money and reducing waste. However, we acknowledge constraints that the one-size mouthpiece may not cater to all. Additionally, the material of the prototype, while tested underwater, requires further improvements to ensure it can withstand varied temperatures, pressure, and prevent water leakage.

User's Getting AUDU On

I practiced what I learned about user experience design in this project, also learned a lot of new knowledge about UX design from Rishabh and Sarah, including SWOT analysis. At the same time I became more proficient in the digital models and the preparation of 3D printing.In particular, how to optimize the zero, thin and overhang faces in the model to meet the standards of 3D printing. Overall, I gained a lot of experience from this project. For the first time, I finished a complete project with a small team of talented people.